Resource Optimization for Circular Textile products

Project Goal

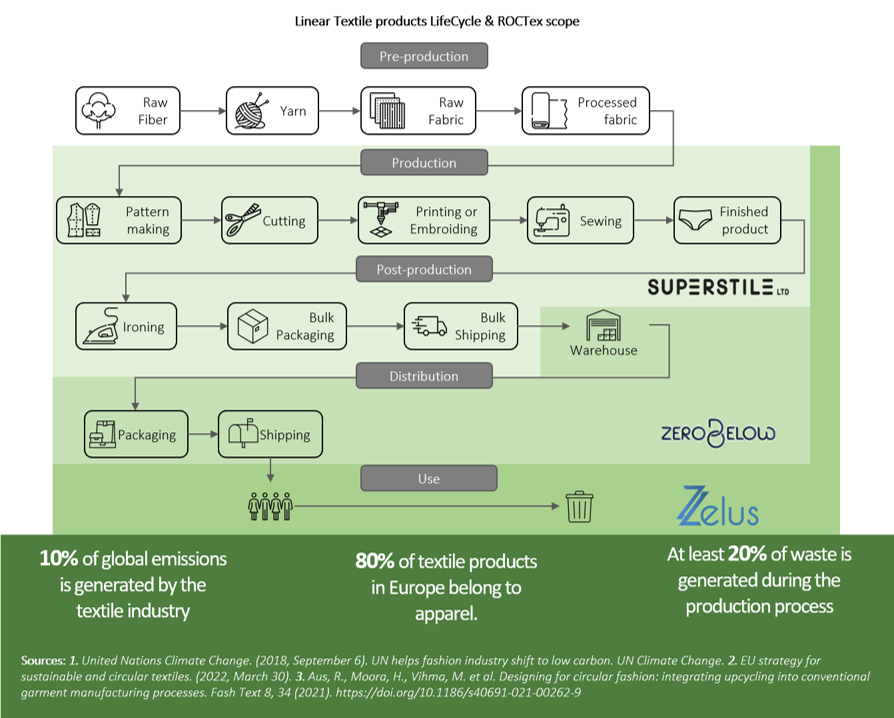

ROCTex is one of the seventeen ideas selected by the KYKLOS 4.0 project consortium to carry out manufacturing experiments using the services and technologies developed in the project. ROCTex focuses on the textile industry and in particular on the garment manufacturing sector and aims to develop a digital solution that will enable producers to accelerate the adoption of technological innovation required in the sector, in order to:

– increase their energy efficiency and their agility;

– reduce their waste during the product design and production processes;

– collect data and digitalize the product life cycle phases in order to build and/or enrich its digital product passport.

ROCTex similarly to the rest of the implementations of the KYKLOS 4.0 selected ideas started in January 2023 and will run for eight months, until the end of August 2023. It aims to complement the real-life experiments of KYKLOS 4.0 for increased energy efficiency and reduction of raw material. The issue is of high importance for the textile industry and in particular the apparel manufacturing which is found to be responsible for up to 10% of the global GHG emissions globally according to the UN. In order to achieve this, we are planning to adopt the “Monitoring and resource optimization with Decision Support” of KYKLOS 4.0 and leverage three promising components, namely: the LCA Simulations Engine, the Data Manager and the Decision Support System. The solution will be implemented on the ZeroBelow products – climate-positive underwear for active users taking into consideration all steps of the value chain and zoom in the manufacturing process (service provided by SUPERSTILE LTD). Apart from the digital solution will also look into potential circular business models for both our partners which will facilitate the minimization of resources use and the prevention of waste generation.

Our objectives

1. Optimize small batch textile production: We are planning to do this by identifying at least 3 best practices for performance optimisation of the production process including suggestions of machinery equipment usage and by identifying ways to improve the efficiency of the resources used (energy and personnel time) by 10% looking at the overall operations of SUPERSTILE in order to improve the benefits for each and every of their clients such as ZeroBelow.

2. Digitally connect the product lifecycle phases: We are planning to realize this by collecting data to build a digital product passport, back-up sustainability claims and determine economic vs environmental costs of future sustainable products. The outputs of this objective will be:

– the reporting on two Circularity Transitioning indicators: renewable energy indicator and circular inflow indicator and on the Reusability Recyclability Recoverability rate indicator prior and post the optimization actions using the Life Cycle Assessment engine.

– the calculation of the environmental impact of three possible future ZeroBelow products, that will be presented vis-à-vis their respective customer financial impact to the ZeroBelow community for feedback in terms of proceeding with their production or not. The latter one is based on the community driven manufacturing model ZeroBelow is embracing.

3. Improve production agility and capacity to satisfy low(er) volume custom demands in an efficient and economic viable way: We are planning to achieve this by increasing the use/repurpose of production textile waste during production by 10% though the better use of textile. We are also planning to design at least 2 circular business model options to enhance circularity in the apparel industry and leverage ROCTex insights.

Do you want to explore what our solution could do for you? Stay tuned and the first tools will start being released soon.